Modern animal husbandry places increasing emphasis on animal welfare, productivity, and facility efficiency. In this context, the hog farrowing crate, also known as sow farrowing crates or raised farrowing crate, has become an indispensable solution in professional pig farming. These specialized systems are designed not only to meet the physiological and behavioral needs of lactating sows and their piglets, but also to enhance farm management by improving survival rates and optimizing space usage. With robust construction and intelligent layout, farrowing crates offer a scientifically engineered environment that benefits both livestock and farmers.

Enhanced Welfare and Recovery for Sows

The primary function of a hog farrowing crate is to provide a secure and comfortable space for sows during childbirth and lactation. These crates are designed with a spacious stall that allows the sow to lie down, stand, and feed comfortably, while reducing stress levels during these critical periods. This controlled environment not only protects the sow from external disturbances but also facilitates rapid postnatal recovery.

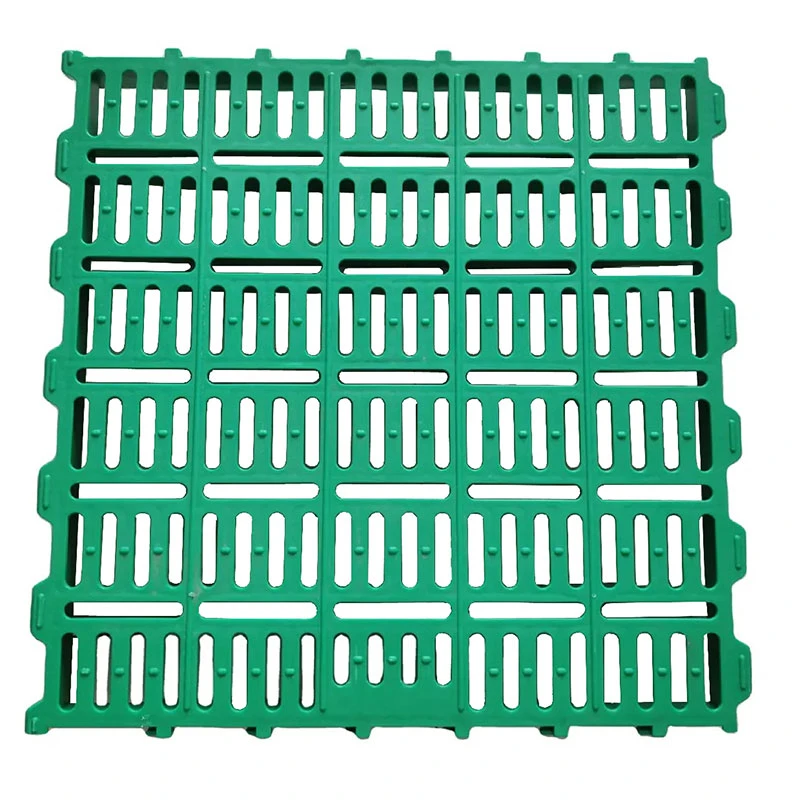

The raised design of many farrowing crates improves hygiene by allowing waste to fall through slatted floors, minimizing contact with contaminants. This layout reduces the risk of bacterial infection and contributes to a cleaner and healthier living space. Additionally, anti-slip flooring and soft padding can be installed to provide physical support for the sow, minimizing the risk of injury during movements or birthing activities.

Ensuring Piglet Safety and Survival

One of the most valuable benefits of using sow farrowing crates is the significantly enhanced safety for piglets. The partitioned structure of the crate limits the sow’s movement in a way that prevents accidental crushing—a leading cause of piglet mortality. With specially designed piglet zones on either side of the sow, newborn piglets can suckle freely without the danger of being laid upon.

Each farrowing crate unit typically includes integrated heating areas or lamps, ensuring optimal warmth for piglets during their early life stages. Maintaining a warm and stable environment is essential for piglet health, particularly in colder climates or seasons. Heat preservation pads may also be installed as needed, further improving the physical condition of piglets and increasing their chances of survival.

Durable Build for Long-Term Use

Modern raised farrowing crate systems are constructed from high-strength steel and welded with precision using MIG technology, ensuring the crates can withstand daily use and the natural behavior of sows. These structures are further enhanced with anti-corrosion surface treatments, such as hot-dip galvanization or zinc diffusion coatings of no less than 80μm. This provides long-term protection against rust and environmental wear, even in high-humidity farm conditions.

Adjustability is another key feature of high-quality farrowing crates. Side panels and stall widths can be modified to accommodate various breeds or sow sizes, enhancing comfort and reducing the likelihood of injury. Strong latching mechanisms and anti-push features are also incorporated to ensure animal security and farm safety.

Tailored Design and Turnkey Solutions for Farms

Whether for small-scale family farms or large commercial operations, farrowing crate systems can be customized to meet specific environmental and operational requirements. Reputable manufacturers offer OEM, ODM, and OBM services to develop optimal crate layouts based on local climate, space availability, and herd size.

Consultation with an experienced supplier ensures that every component—from crate dimensions to flooring material and heating elements—is tailored to maximize productivity while maintaining high standards of animal welfare. Installation support and after-sales service further guarantee smooth implementation and operational reliability.

Hog Farrowing Crate FAQs

What are the key features that make a hog farrowing crate effective?

A hog farrowing crate should offer a balance of sow comfort and piglet safety. Key features include adjustable partitions, piglet zones with heating elements, anti-slip flooring, and corrosion-resistant materials. These features collectively improve hygiene, reduce piglet mortality, and facilitate sow recovery after birth.

Why is the raised farrowing crate design preferred in modern pig farms?

The raised design promotes better waste management by allowing manure and waste to fall through slatted floors, keeping the surface dry and clean. This not only enhances hygiene and reduces infection risks but also improves the overall working conditions for farm staff.

How does a farrowing crate help increase piglet survival rates?

Farrowing crates limit the sow's movement, preventing her from accidentally crushing piglets. They also include separate heated areas for piglets, which provide the warmth necessary for early development and survival, especially in cooler environments.

What materials are commonly used to construct sow farrowing crates?

Most farrowing crates are made from heavy-duty galvanized steel or stainless steel, often with MIG welding for strength. Surfaces are coated with anti-corrosion treatments like zinc diffusion to ensure longevity, especially in the humid and acidic environments of pig farming.

Can hog farrowing crates be customized for different pig breeds or farm sizes?

Yes. Manufacturers often offer customization options through OEM and ODM services. These options allow crate dimensions, materials, flooring types, and heating systems to be tailored according to the specific requirements of different breeds or farm setups, ensuring efficiency and welfare optimization.

Post time: Jul . 31, 2025