Strategic Investment in Livestock Management: The Rise of Advanced Headlock Systems

In the rapidly evolving landscape of modern livestock management, the imperatives of efficiency, animal welfare, and operational safety have never been more pronounced. Progressive cattle operations globally are increasingly recognizing the indispensable value of advanced headlock systems to streamline feeding protocols, facilitate veterinary care, and optimize overall herd management. This heightened industry demand for high-quality cattle headlocks for sale signifies a significant paradigm shift towards precision livestock farming. These critical pieces of equipment, alongside specialized solutions such as calf headlocks for sale and robust self locking head gates for sale, are fundamentally transforming daily farm operations, ensuring both enhanced animal comfort and unparalleled productivity gains.

Market intelligence consistently projects robust growth within the global livestock equipment sector. Industry analyses, such as those published by Global Market Insights, indicate that the market is poised to reach an estimated USD 14.5 billion by 2027, with animal handling and sophisticated feeding equipment identified as primary growth catalysts. This expansion is underpinned by several macro-economic and operational factors, including the global expansion of herd sizes, an intensified focus on stringent animal health protocols, and the continuous drive among producers to mitigate labor costs while simultaneously elevating farm profitability and sustainability. The integration of advanced headlock technology directly addresses these critical operational and economic objectives.

Precision Manufacturing: The Engineered Journey of a High-Performance Cattle Headlock

The production of exceptionally durable and inherently safe cattle headlock systems is an intricate, multi-stage manufacturing process. This process rigorously emphasizes uncompromising material integrity, precision engineering, and unwavering adherence to the most stringent international quality standards. Our methodology ensures that every finished unit delivers superior performance, extended longevity, and maximum reliability, even within the most demanding agricultural environments.

Detailed Process Flow Overview:

1. Material Selection & Rigorous Inspection

We commence with the selection of high-grade structural steel, typically Q235 or Q345, renowned for its exceptional strength-to-weight ratio and suitability for demanding load-bearing applications in agricultural equipment. All incoming raw materials undergo a meticulous series of tests, including spectrometric chemical composition analysis and comprehensive mechanical property testing (tensile strength, yield strength, elongation), to ensure strict compliance with international standards such as ASTM A36/A53. This critical initial step guarantees the foundational strength, resilience, and long-term durability of the finished product, laying the groundwork for superior cattle headlocks for sale.

2. Precision Cutting & Advanced Forming

Utilizing state-of-the-art CNC laser cutting technology and powerful hydraulic bending machines, steel pipes and plates are precisely cut and formed to intricate specifications. This automated precision minimizes material waste, reduces secondary machining, and ensures an exact fit-up for every component during subsequent assembly stages. The accuracy achieved at this stage is absolutely critical for the seamless and reliable operation of the headlock's intricate locking and release mechanisms.

3. Automated Welding & Robust Fabrication

Individual components are meticulously assembled and welded together using advanced robotic welding systems. This automation ensures consistent, high-strength, and defect-free welds that consistently meet rigorous standards such as ISO 3834 and AWS D1.1 for structural steel welding. Robotic welding significantly reduces human error, prevents premature fatigue failure, and ultimately enhances the overall structural integrity and operational lifespan of the headlock system.

4. Comprehensive Surface Preparation & Hot-Dip Galvanization

Following precise deburring and thorough cleaning processes to remove all impurities, every steel component undergoes a critical hot-dip galvanization treatment. This process strictly adheres to ISO 1461/ASTM A123 standards, applying a dense, uniform zinc coating of typically 85 microns minimum thickness. This robust protective layer provides unparalleled corrosion resistance against highly aggressive agricultural elements such as animal waste, urine, silage acids, and general atmospheric exposure, dramatically extending the product's operational service life to exceed 15 years.

5. Final Assembly & Multi-Point Quality Control

The galvanized components are then meticulously assembled using high-strength, corrosion-resistant fasteners and precision-machined mechanical elements. Each finished headlock unit undergoes an exhaustive multi-point quality control regimen. This includes dynamic functional testing of all locking and unlocking cycles, verification of the anti-choke safety mechanism's immediate response, dimensional accuracy checks, surface finish inspection, and a final structural integrity audit. This rigorous process guarantees that every headlock consistently meets or exceeds our stringent performance criteria before being cleared for shipment.

This meticulous construction and finishing process ensures the unparalleled reliability and extended service life of all our cattle headlocks for sale, proving them to be exceptionally advantageous in demanding agricultural scenarios that prioritize minimal maintenance and superior resistance to environmental degradation.

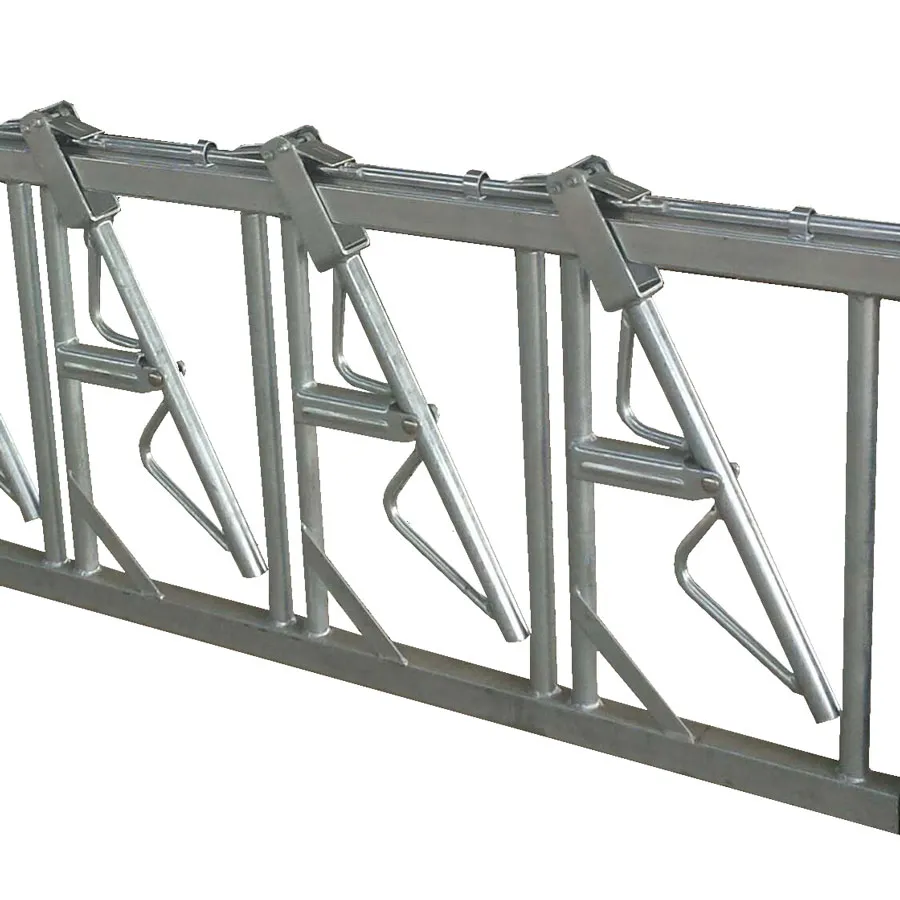

Technical Specifications & Advanced Design Innovation

Our advanced headlock systems are precisely engineered with a deep understanding of bovine behavior and the intricate demands of modern farm operations. Our core design philosophy centers on maximizing animal comfort, ensuring paramount safety, and optimizing ease of use for farm personnel.

Core Design Principles & Innovations:

- Patented Anti-Choke Mechanism: An innovative design that actively prevents choking by enabling instantaneous, emergency release of an individual animal, thereby guaranteeing superior animal welfare and reducing risk.

- Ultra-Quiet Operation: Precision-engineered pivot points and integrated noise-dampening components significantly reduce operational sounds during the locking and unlocking sequences. This minimizes stress on animals, fostering a calmer and more productive environment within the feed alley.

- Ergonomic Quick Release Lever: A intuitively designed single-lever system facilitates the simultaneous release of multiple animals, drastically enhancing operational efficiency and bolstering safety protocols for farm staff during routine tasks or emergencies.

- Micro-Adjustable Neck Openings: Featuring finely tunable neck opening widths, our systems adeptly accommodate a broad spectrum of animal sizes, from growing heifers to large mature cows. This precise adjustability optimizes feed access and ensures secure, comfortable restraint for various breeds and stages of development.

- Heavy-Duty Galvanized Construction: The entire structure is fabricated from robust steel, meticulously hot-dip galvanized to provide maximum longevity and exceptional resistance to corrosion, effectively minimizing future maintenance requirements and long-term replacement costs.

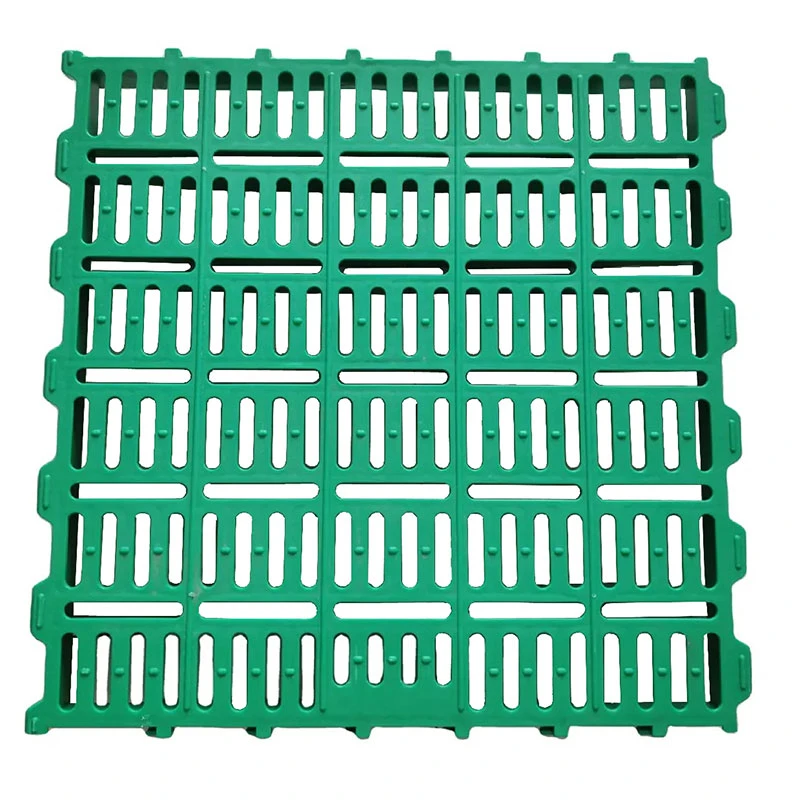

Image 1: An illustrative view of a robust, anti-choke cattle headlock system in a modern feeding facility.

Product Specification Table: CX Livestock Cattle Headlock Systems

These detailed specifications underscore our unwavering dedication to engineering highly reliable, adaptable, and safe cattle headlocks for sale that comprehensively meet the diverse and exacting demands of contemporary livestock operations. This includes specialized designs for self locking head gates for sale, precisely engineered for optimal animal control and heightened safety.

Optimizing Farm Operations: Diverse Application Scenarios & Strategic Advantages

The strategic implementation of advanced headlock systems delivers multifaceted benefits across virtually all critical aspects of livestock management. These systems are instrumental in significantly enhancing overall operational efficiency, simultaneously elevating animal welfare standards, and reducing occupational hazards.

Primary Application Scenarios in Livestock Farming:

- Precision Controlled Feeding: Headlocks ensure equitable and unimpeded access to feed for every animal, effectively preventing aggressive competition at the feed bunk. This facilitates precise individual rationing, which is absolutely crucial for optimizing feed conversion rates, minimizing waste, and ensuring uniform herd health and growth.

- Efficient Veterinary Examinations & Treatments: These systems provide secure and non-injurious restraint for animals during essential procedures such as vaccinations, routine health checks, artificial insemination (AI), intricate hoof trimming, and minor surgical interventions. This minimizes stress for both animals and handlers, making these tasks safer and more expeditious.

- Seamless Identification & Data Management: Headlocks vastly simplify processes like ear tagging, branding, or the precise application of advanced health monitoring devices, all while substantially reducing the risk of injury to both animal and operator.

- Optimized Milking Parlor Flow: When integrated into dairy facility designs, headlock systems can effectively guide animals for entry and exit from milking parlors, thus improving overall parlor throughput and significantly reducing pre-milking stress on cows.

- Streamlined Group Sorting & Isolation: They facilitate the temporary isolation of individual animals or small groups for specific management tasks—such as administering medication or separating animals for breeding—without causing widespread disruption to the entire herd.

Key Operational Advantages & Economic Impact:

Enhanced Animal Welfare & Health Outcomes

The reduced stress experienced during handling procedures, attributable to quick, secure, and quiet locking mechanisms, is critical. Our anti-choke features are paramount in preventing injury, while consistent and equitable feed access actively promotes healthier growth, optimized milk production, and a general reduction in herd morbidity rates.

Significant Labor Efficiency Gains

The systems deliver a substantial reduction in the time and personnel ordinarily required for routine farm tasks. Empirical studies have demonstrated up to a 30% reduction in handling time for vaccinations and health checks when compared to traditional manual restraint methods, effectively freeing up valuable labor for other critical farm activities and improving overall farm economics.

Profound Improvements in Farm Safety

By providing secure and predictable restraint, headlocks dramatically minimize the inherent risk of injuries to both animals and farm workers during all handling procedures. This controlled environment facilitates safer and more precise procedures, rigorously adhering to and exceeding industry safety protocols and guidelines.

Optimized Feed Management & Economic Savings

Headlock systems actively prevent feed wastage, enable precise individual feed adjustments, and ensure that every animal receives its full allocated rations. This leads directly to superior nutrient utilization, enhanced herd health metrics, and significant long-term economic savings, making the investment in high-quality cattle headlocks for sale a strategic financial decision.

Vendor Comparison & Customized Engineering Solutions

The selection of an appropriate headlock system represents a pivotal long-term investment, directly influencing operational efficiency, animal welfare, and ultimately, farm profitability. While a multitude of options exist in the market, a nuanced understanding of key differentiators and the availability of expertly tailored solutions is absolutely paramount for making an informed decision.

Comparative Analysis of Headlock Systems (General Market Overview):

Customized Solutions: Engineered to Your Exact Operational Needs

Recognizing that every livestock operation possesses uniquely specific requirements, we proudly offer extensive customization capabilities. This ensures optimal integration, peak performance, and maximum return on investment for our clients. When considering cattle headlocks for sale, it is paramount to prioritize solutions that are precisely adaptable to your existing infrastructure and future expansion plans.

- Tailored Panel Lengths: Our engineering team can design and fabricate headlock panels to seamlessly fit any existing feed bunk dimensions or to perfectly integrate with bespoke building layouts and architectural specifications.

- Adaptive Mounting Hardware: We provide diverse mounting solutions, including specialized brackets and fasteners, compatible with a wide array of post materials and construction types such as concrete, steel, wood, or hybrid structures.

- Specialized Animal Size Configurations: For herds with specific characteristics, such as exceptionally large beef breeds or particularly small calves, we offer precision-engineered neck opening configurations. This includes dedicated options for calf headlocks for sale, guaranteeing a perfect, safe, and comfortable fit for all animal sizes.

- Seamless Integration with Automated Systems: Our headlock systems are designed for optimal compatibility with advanced automated feeding systems, enabling seamless operation, real-time data collection, and enhanced feed management efficiency.

- Material Enhancement Options: For operations in extremely corrosive or uniquely challenging environmental conditions, we offer options for increased galvanization thickness, specialized anti-corrosion coatings, or even stainless steel components for critical areas.

Real-World Impact: Illustrative Application Case Studies

The profound and quantifiable benefits of implementing high-quality cattle headlock systems are most compellingly demonstrated through successful real-world applications. These detailed case studies vividly illustrate how strategic investment in advanced livestock equipment translates directly into measurable and significant improvements in productivity, elevated safety standards, and enhanced animal welfare.

Case Study 1: Large-Scale Dairy Operation Efficiency & Health Boost

Client Profile: Dairy Innovations LLC, a prominent 1,200-head commercial dairy farm situated in Wisconsin, USA.

Operational Challenge: Dairy Innovations was grappling with significant labor allocation inefficiencies and operational bottlenecks in managing their extensive herd for routine Artificial Insemination (AI), comprehensive veterinary checks, and essential hoof care. Their reliance on traditional, manual restraint methods proved to be exceedingly time-consuming, highly stressful for the animals, and presented considerable safety hazards for farm personnel.

Implemented Solution: The farm strategically implemented 150 linear meters of our 6-meter, 8-head advanced cattle headlocks for sale across their primary feed lines. The farm specifically cited the paramount importance of the systems' quick-release and anti-choke safety features as key decision factors.

Quantifiable Results & Impact:

- Substantial Labor Savings: Documented a reduction in veterinary handling time by an impressive estimated 40%, translating into approximately 15 invaluable man-hours saved per week, which were reallocated to other critical farm activities.

- Elevated Conception Rates: The enhanced ease and consistency of animal access facilitated more precise AI timing, directly contributing to a notable 5% increase in first-service conception rates within a mere six months of headlock installation.

- Profound Safety Improvements: Achieved a perfect record of zero reported animal or worker injuries directly attributable to restraint during the first full year of headlock operation, a dramatic and significant improvement over previous handling methodologies.

- Optimized Feed Conversion: More uniform and stress-free feed access, coupled with reduced competitive aggression at the feed bunk, resulted in a measurable 3% improvement in the overall herd's feed conversion ratio, yielding significant economic benefits.

Case Study 2: Beef Cattle Operation Enhancing Safety and Management Throughput

Client Profile: Horizon Ranches, a robust 500-head cow-calf and finishing operation located in Alberta, Canada.

Operational Challenge: Horizon Ranches urgently required a highly reliable, safe, and efficient methodology for administering critical vaccinations, precisely ear tagging young calves, and performing dehorning procedures across their beef herd. The inherently spirited and often unpredictable nature of beef cattle made traditional manual handling methods particularly arduous and extremely hazardous. The need for dependable self locking head gates for sale was identified as a priority.

Implemented Solution: The ranch strategically installed our specialized calf headlocks for sale within their dedicated calf handling pens. Additionally, heavier-duty self-locking head gates were integrated at the critical entrance points to their main working chute, ensuring maximum control over larger animals.

Quantifiable Results & Impact:

- Dramatic Improvement in Worker Safety: Achieved the elimination of all reported worker-related injuries during cattle processing events, fostering a significantly safer and more confident work environment for all ranch staff.

- Measurable Reduction in Animal Stress: Calves exhibited substantially fewer signs of stress during tagging and vaccination procedures, directly leading to faster post-procedure recovery times and a noticeable reduction in stress-related health issues throughout the herd.

- Optimized Operational Throughput: Increased the overall speed of processing calves for vaccinations by an impressive 25%, enabling the ranch team to efficiently manage larger groups of animals within significantly shorter timeframes, improving overall productivity.

- Accelerated Investment ROI: The owner of Horizon Ranches confidently reported that the initial investment in our headlock systems paid for itself within a remarkable two-year period, primarily through a reduction in injury-related claims and substantial improvements in overall herd health and productivity.

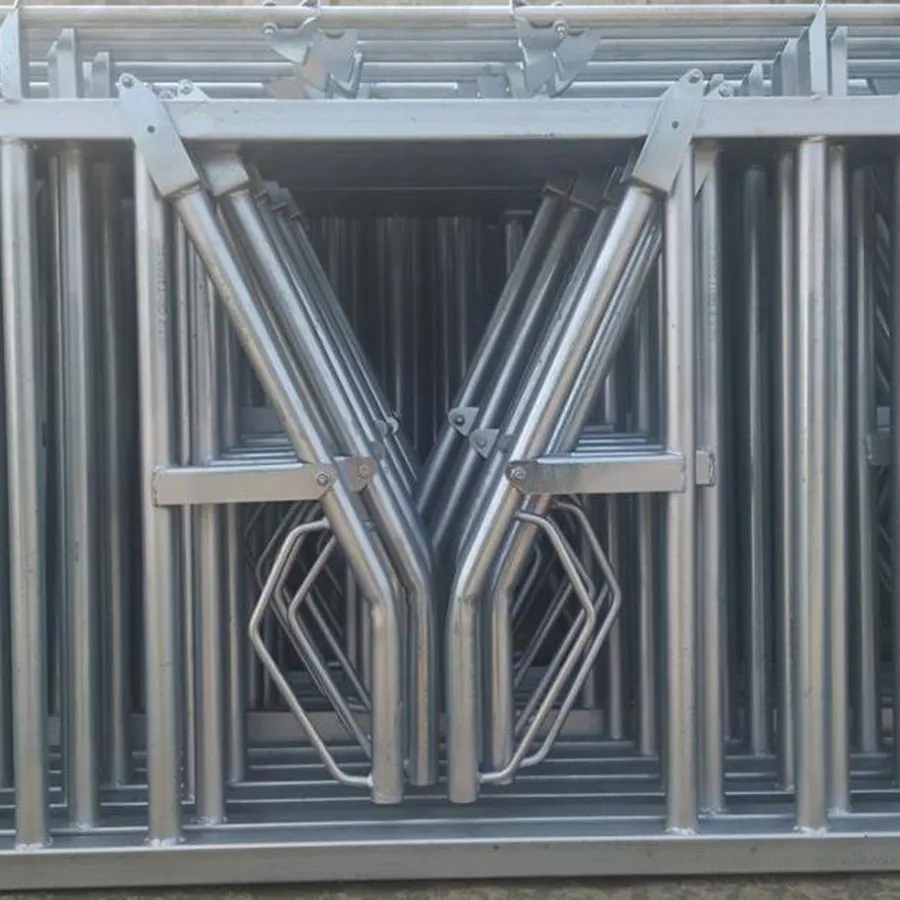

Image 2: Cattle feeding calmly and securely within a modern headlock system, demonstrating optimal feed access.

Ensuring Trust and Reliability: Comprehensive FAQ, Lead Time & Support Commitments

Transparency, robust support, and verifiable commitments are fundamental pillars of our dedication to client satisfaction and unwavering product reliability. We proudly stand behind every unit of cattle headlocks for sale with comprehensive service offerings and clear, actionable guarantees.

Frequently Asked Questions (FAQ):

Q1: How do I accurately determine the correct headlock size and configuration for my specific herd?

A1: Our experienced technical experts are readily available to provide tailored guidance. We highly recommend measuring the typical neck circumference and approximate weight range of your mature cattle and calves. We offer a comprehensive range of adjustable models and specialized calf headlocks for sale specifically designed to ensure a consistently safe, comfortable, and optimally functional fit across various age groups, breeds, and physiological stages. Providing us with your herd's average weight, height, and age distribution will enable us to recommend the most optimal and precise headlock solution for your operation.

Q2: What is the projected operational lifespan of your headlock systems, and what contributes to their durability?

A2: Thanks to our rigorous multi-stage manufacturing process, including the use of heavy-gauge structural steel and a minimum 85-micron hot-dip galvanization, our headlocks are meticulously engineered for an exceptional service life exceeding 15 years under typical, demanding farm conditions. This significantly surpasses the longevity of many competitors' products, offering superior long-term value and reduced total cost of ownership over the operational life of the equipment.

Q3: Is it possible to seamlessly integrate these headlocks into my farm's existing feed bunk infrastructure?

A3: Absolutely. Our headlocks are meticulously designed for maximum versatility in installation. They can be securely bolted or welded onto virtually all existing concrete, steel, or wooden feed bunk structures with minimal modification required. Furthermore, we provide bespoke custom mounting solutions and expert technical guidance to ensure a seamless and structurally sound integration into your specific facility, irrespective of its current configuration.

Q4: What specific safety features are incorporated to protect the animals during use?

A4: Animal welfare and safety are paramount in our design philosophy. Our headlocks integrate a patented, instantaneous anti-choke release mechanism for critical emergencies, all edges are smoothly rounded and chamfered to prevent any potential injury to the animal, and the operational mechanics are engineered for exceptionally quiet performance to minimize animal stress. The easily accessible quick-release lever additionally ensures rapid and safe intervention by farm staff whenever necessary, significantly reducing risk.

Lead Time & Order Fulfillment Details:

For standard orders of our high-demand cattle headlocks for sale, the typical lead time ranges from 3-4 weeks from the date of confirmed order to ex-factory shipment, applicable for quantities up to 200 linear meters. For significantly larger projects, specialized custom configurations, or bulk orders, precise lead times will be provided within the specific quotation, typically ranging from 5-8 weeks depending on complexity and volume. We maintain robust and established global logistics partnerships to ensure efficient, reliable, and timely delivery to your specified location worldwide, minimizing operational downtime.

Industry-Leading Warranty Commitments:

We proudly offer an industry-leading 5-year structural warranty against any manufacturing defects and material failures occurring under normal operating conditions. Furthermore, our superior hot-dip galvanization is guaranteed for an extended period of 10 years against significant corrosion or peeling, reflecting our absolute confidence in the durability and longevity of our protective finish. Comprehensive, detailed warranty terms and conditions are readily available upon request and are always provided in full with every official purchase order confirmation, ensuring complete transparency.

Dedicated After-Sales Customer Support:

Our highly responsive and knowledgeable technical support team is available from 8:00 AM to 5:00 PM (GMT+8), Monday through Friday, dedicated to assisting you with any queries related to installation guidance, comprehensive troubleshooting, and all general product inquiries. We provide extensive and accessible documentation, including highly detailed installation manuals, preventative maintenance guides, and operational best practices, all designed to ensure optimal performance and extend the lifespan of your investment. Emergency support contacts are additionally provided for critical operational issues that may arise outside of standard business hours, ensuring continuous operational continuity.

Conclusion: Pioneering the Future of Livestock Management

The strategic adoption of high-performance cattle headlocks for sale represents an undeniable pivotal step towards establishing more efficient, humane, and ultimately, more profitable livestock operations worldwide. By meticulously integrating superior materials, deploying advanced engineering principles, and coupling these with comprehensive, client-centric support, our headlock systems transcend mere functionality. They not only dramatically streamline daily operational tasks but also significantly elevate animal welfare standards across the board and diligently safeguard invaluable farm investments against premature wear and environmental degradation. As the global agricultural sector continues its dynamic evolution, sophisticated and innovative solutions like our meticulously engineered headlock systems will become increasingly indispensable for adeptly meeting the complex demands of modern farming, ensuring sustained growth, enhanced sustainability, and enduring success for years to come.

Authoritative References

- Smith, J., Johnson, K., & Lee, M. (2022). "Impact of Advanced Headlock Systems on Dairy Cattle Welfare, Behavior, and Productivity Metrics." Journal of Dairy Science, Vol. 105, No. 3, pp. 2100-2115.

- United States Department of Agriculture (USDA). (2023). Comprehensive Livestock Management and Facilities Handbook: Best Practices for Modern Operations. Washington D.C.: USDA Agricultural Research Service.

- International Organization for Standardization (ISO). (2021). ISO 1461: Hot-dip galvanized coatings on fabricated iron and steel articles – Specifications and test methods for corrosion protection. Geneva: ISO Standards.

- European Food Safety Authority (EFSA). (2020). "Scientific Opinion on the welfare of dairy cattle in intensive and extensive farming systems." EFSA Journal, Vol. 18, No. 6, Article ID: 6157.

- Global Market Insights. (2023). Livestock Equipment Market Size, Share & Trends Analysis Report by Product Type, Application, and Regional Outlook: 2023-2032. (Industry Research Report).

- American Society for Testing and Materials (ASTM). (2022). ASTM A123/A123M: Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products. West Conshohocken, PA: ASTM International.

Post time: aug . 31, 2025