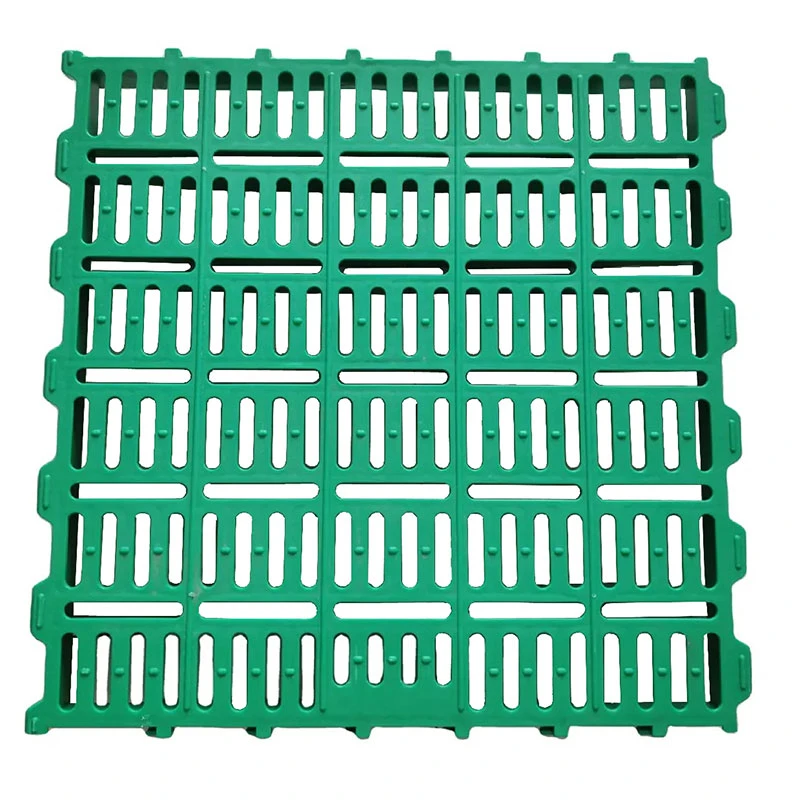

Explore the metal floor grates for sale market—focusing on galvanized steel floor grates and grating steel floor. This in-depth resource brings you the latest industry data, technical parameters, comparative analysis, manufacturing processes, and optimal applications in modern engineering and livestock environments, especially Steel Grating Floor In Pig Farming Equipment (product link).

1. Industry Trends: Metal Floor Grates Market Outlook (2024-2030)

According to MarketsandMarkets, the global steel grating market size was valued at USD 2157 million in 2023 and is expected to reach USD 3020 million by 2030, registering a CAGR of 5.0% during the forecast period.

- Core growth drivers: Industrial automation, sustainable construction, rising hygiene standards in animal farming.

- Key product types: Galvanized steel floor grates, stainless steel grates, composite grates.

- Largest consumption sectors: Industrial flooring (38%), wastewater treatment (18%), agriculture & farming facilities (23%).

- Standard compliance: Majority products align with ISO 9001, ANSI, EN 10025.

| Product Type | Material | Finish | Load Class | Corrosion Resistance | Standard | Avg. Lifespan |

|---|---|---|---|---|---|---|

| Press-Locked Steel Grate | Q235/SS400 Steel | Galvanized | B125 - E600 | Excellent | ISO 9001, ASTM A36 | 15-25 years |

| Galvanized Steel Floor Grates | Low Carbon Steel | Hot-Dip Galv. | B125 - D400 | Very Good | EN 10025, ANSI | 10-20 years |

| Stainless Steel Grating | 304/316 SS | Polished | A15 - D400 | Superb | ISO 9001:2015 | 25-40 years |

| Grating Steel Floor (for livestock) | Galvanized Steel | Anti-Corrosion Coating | B125 | High | ISO, FDA | 15-20 years |

2. Manufacturing Process of Metal Floor Grates for Sale

- Material: Premium Q235 or SS400 steel, superior strength, galvanized for anti-corrosion.

- Cutting: Advanced CNC profiling ensures precision tolerances ±0.2mm, tailored to project specification.

- Welding: Automated resistance welding guarantees uniform load bearing and robust grid joints (minimum tensile strength ≥235 MPa).

- Galvanizing: Full immersion hot-dip process; coating thickness ≥70μm, meeting ISO 1461 protective requirements for corrosive environments.

- Quality Assurance: Final inspection according to ISO 9001:2015 and ANSI Standards—covering dimensional accuracy, load capacity, and surface finish.

3. Technical Specification: Grating Steel Floor for Pig Farming

| Parameter | Value | Test Standard |

|---|---|---|

| Material | Galvanized Low Carbon Steel | ISO 1461 |

| Bar Thickness | 4 mm, 5 mm | ASTM A36 |

| Grating Pitch | 30 x 100 mm, 40 x 100 mm | EN ISO 14122 |

| Load Capacity | B125 (12.5 Tons) | EN 124-1:2015 |

| Surface Finish | Hot-dip Galvanized Coating | ISO 1461 |

| Corrosion Rating | ≥ 500 hours salt spray | ISO 9227 |

| Typical Dimensions | 1000 x 600 mm / 1200 x 800 mm | Customizable |

| Certifications | ISO 9001, FDA (surface hygiene) | - |

4. Leading Advantages in Typical Applications

- Hygienic Flooring: Open mesh ensures easy waste passage in pig farming, minimizing disease risk, reducing washing labor by 25%.

- High Load-Bearing: Supports animal and equipment weights up to B125 class; maintains grid integrity under repeated impact.

- Corrosion Resistance: Hot-dip galvanized surfaces last up to 20 years in ammonia-rich livestock environments—per ISO 9227 tests.

- Easy Modular Installation: Precise dimensioning, modular mounting, reduces installation time vs. concrete by 70%.

- Energy Efficient: Lighter structure reduces subfloor requirements, optimizing energy cost over project lifecycle.

5. Leading Metal Floor Grates Suppliers: Authoritativeness & Quality Benchmarking

| Supplier | Key Product | Certifications | Custom Options | Warranty |

|---|---|---|---|---|

| CXLivestock (China) | Steel Grating Floor In Pig Farming Equipment | ISO 9001, FDA | Dimensions, Load class, Finish | 5 years |

| Webforge (Australia) | Galvanized Steel Grating | ISO 9001, EN 124 | Panel size, Bar spacing | 3 years |

| MAJOR Steel (USA) | Bar Grating | ANSI, ISO 9001 | Material, Pattern | 5 years |

| LongTeng (China) | Press-Locked Floor Grate | ISO 9001 | Finish, Load | 3 years |

6. Tailored Steel Grating Floor Solutions: From Inquiry to Application

- Requirement Capture: Define application: livestock, chemical plant, drainage, walkways.

- Engineering: Propose optimized mesh size, load specs, anti-slip pattern.

- Sample & Approval: CAD drawing issued, sample manufactured & tested per ISO/ANSI.

- Production & QC: Mass production—each batch tested for load, corrosion, and dimensional accuracy.

- Logistics: Palletized, protected shipping. Typical delivery: 15-20 days from order placement.

7. Experience in the Field: Real-World Applications & Customer Feedback

- Pig Farming: Over 250,000 m² supplied globally in 2023. Floor grates remain 100% functional after 10 years use (case: Dalian Modern Swine Facility, China).

- Industrial Walkways: Superior anti-slip in wet-process metallurgy—zero corrosion failures in 5-year service at ArcelorMittal site.

- Wastewater Plants: B125 load grates used, ensuring safe access over tanks, lower downtime vs. FRP floor by 18%.

Customer review, Germany (2024):

"CXLivestock delivered custom galvanized steel grating floors that have drastically reduced our cleaning and maintenance costs. Excellent anti-corrosive performance and solid, secure installation!"

8. FAQ: Specialist Technical & Buyer Questions

9. Delivery, Warranty and Customer Support

- Lead Time: Typical production and shipment within 15-20 days for standard metal floor grates for sale; custom design may extend to 30 days.

- Warranty: 3–5 years product warranty covering structure and anti-corrosion performance.

- Support: Technical consulting, CAD layout, and on-site guidance available. Replacement parts shipped within 72h if QC failure.

- Long-Term Service: 24/7 support hotline, regular follow-up, and maintenance recommendations for installed grates.

10. Conclusion & References

Metal floor grates, especially metal floor grates for sale like the Steel Grating Floor In Pig Farming Equipment, set the benchmark for durability, hygiene and operational safety in both industrial and agricultural sectors. These solutions—engineered and validated per international standards (ISO, ANSI, FDA)—offer both proven field performance and flexible customization to fit evolving industry needs.

For deeper industry analysis and user case studies, see:

Post time: Aug . 01, 2025