The Indispensable Role of Galvanised Sheep Hurdles in Modern Livestock Management

In contemporary livestock management, efficient and humane animal handling is paramount. For sheep farmers, the cornerstone of this efficiency often lies in robust and reliable fencing solutions. Galvanised sheep hurdles for sale represent a critical investment, offering unparalleled durability and versatility compared to their untreated counterparts. These hurdles are essential for creating temporary pens, directing flocks, facilitating sorting, and managing grazing patterns across diverse agricultural landscapes. Our product, the Sheep Fence And Restraint In Sheep Farming Equipment, is specifically engineered to meet the rigorous demands of modern sheep farming, ensuring operational fluidity and animal welfare. The unique properties of galvanised steel ensure prolonged service life and minimal maintenance, making them a cost-effective solution for both smallholders and large-scale commercial operations.

The demand for high-quality sheep handling equipment is driven by several industry trends, including increasing flock sizes, a greater emphasis on animal welfare standards, and the need for adaptable farming infrastructure. Farmers are increasingly seeking solutions that are easy to deploy, reconfigure, and clean, while also resisting the harsh environmental conditions inherent in outdoor livestock rearing. This has propelled the market for advanced galvanised hurdles, pushing manufacturers to innovate in design, material strength, and corrosion protection. Understanding the underlying technology and benefits of these critical components is key to making informed procurement decisions that will impact farm productivity and profitability for years to come.

The Manufacturing Excellence: Crafting Durable Sheep Hurdles

The superior performance of galvanised sheep hurdles for sale stems from a meticulously controlled manufacturing process designed for strength and longevity. The journey begins with the selection of high-grade steel, typically conforming to international standards such as ASTM A36 or S235JR, known for its excellent weldability and structural integrity. This ensures the hurdles can withstand significant impact and dynamic forces exerted by livestock without deformation.

Manufacturing Process Highlights:

- Material Preparation: Steel tubes and bars are precisely cut to specifications using advanced CNC laser cutting or cold sawing techniques, minimizing material waste and ensuring dimensional accuracy.

- Welding: Components are assembled and fusion-welded using MIG/MAG (Metal Inert Gas/Metal Active Gas) welding processes. This provides strong, clean welds that are critical for the structural integrity of the hurdles. Our experienced welders adhere to AWS D1.1 structural welding code standards, ensuring every joint offers maximum load-bearing capacity.

- Hot-Dip Galvanization: This is the hallmark of quality. After fabrication, the steel hurdles undergo a comprehensive cleaning process (degreasing, pickling in acid, fluxing) to remove impurities. They are then immersed in a bath of molten zinc at approximately 450°C (840°F). The zinc metallurgically bonds with the steel, creating a series of zinc-iron alloy layers and an outer layer of pure zinc. This coating, typically 85 microns thick, provides cathodic protection and an impenetrable barrier against corrosion. This process adheres strictly to ISO 1461 standards, guaranteeing a minimum service life of 20-30 years in typical agricultural environments.

- Quality Control & Testing: Each batch of galvanised hurdles undergoes rigorous quality checks. This includes visual inspection for weld integrity and coating uniformity, non-destructive testing (NDT) such as ultrasonic testing for critical welds, and adhesion tests on the galvanized coating. Furthermore, dimension checks against engineering drawings are performed to ensure consistency.

The robust construction and superior anti-corrosion properties of these hurdles mean they are highly resistant to environmental degradation, even when exposed to harsh weather, animal waste, and agricultural chemicals. This significantly reduces the need for frequent repairs or replacements, offering long-term economic benefits and ensuring farm operations run smoothly without interruptions due to equipment failure.

Technical Specifications and Performance Advantages

When evaluating sheep hurdles for sale, understanding the precise technical specifications is crucial for matching the equipment to specific farming needs. The dimensions, material gauge, and galvanization quality directly impact durability, weight, and handling characteristics. Below is a table outlining typical parameters for high-quality galvanised sheep hurdles:

| Parameter | Typical Range/Value | Importance |

|---|---|---|

| Standard Length | 1.2m to 3.6m (4ft to 12ft) | Versatility for various pen sizes and lane configurations. Common sizes include 6ft sheep hurdles for sale. |

| Standard Height | 0.95m to 1.1m (3.1ft to 3.6ft) | Prevents sheep from jumping over while allowing easy handling by personnel. |

| Frame Material | 25mm to 38mm OD (Outer Diameter) Steel Tube | Contributes to structural rigidity and resistance to bending under pressure. |

| Infill Bars | 16mm to 20mm Solid Steel Bar | Prevents sheep from getting through while maintaining visibility and airflow. |

| Galvanization Thickness | Minimum 85 microns (ISO 1461) | Crucial for long-term corrosion resistance, directly impacts service life. |

| Weight (e.g., 6ft hurdle) | Approx. 15-20 kg (33-44 lbs) | Balances stability with ease of handling and transportation. |

The primary advantage of hot-dip galvanization is its superior corrosion resistance compared to other coatings or untreated steel. The zinc coating acts as a sacrificial layer, protecting the underlying steel even if minor scratches occur. This means the hurdles can withstand constant exposure to moisture, animal waste, and varying temperatures without succumbing to rust. This inherent durability translates into a significantly extended service life, often exceeding 20 years, minimizing replacement costs and maintenance efforts for farmers.

Versatile Applications Across the Livestock Sector

The versatility of galvanised sheep hurdles for sale makes them indispensable tools across numerous applications within the livestock industry, primarily sheep farming. Their modular design allows for rapid deployment and reconfiguration, adapting to dynamic farm needs. Key application scenarios include:

- Temporary Pens and Holding Areas: Quickly establish secure enclosures for lambing, shearing, drenching, or veterinary examinations. This is particularly useful during peak seasons when additional space is required.

- Field Subdivisions & Grazing Management: Implement rotational grazing systems by sectioning off pastures, optimizing forage utilization and promoting pasture health. Hurdles allow for flexible adaptation of grazing areas based on flock size and forage availability.

- Handling Systems & Race Building: Construct efficient sheep handling races for sorting, weighing, and dipping. The robust nature of galvanised hurdles ensures the safety of both animals and handlers during these intensive operations.

- Farm Shows and Events: Provide safe and reliable containment for animals at agricultural shows, sales, and competitions, where ease of setup and disassembly is crucial.

- Boundary Fencing & Security: While primarily for internal management, they can also serve as temporary boundary fences or strengthen existing perimeters where additional security or animal control is needed.

For instance, farmers utilizing our sheep hurdles for sale consistently report improved efficiency in their daily routines, reducing the physical strain on workers and minimizing stress for the animals. The availability of various lengths, such as the popular 6ft sheep hurdles for sale, ensures that bespoke layouts can be achieved with minimal effort, catering to diverse land configurations and operational requirements. The ability to quickly and securely link hurdles together using drop pins or integrated connections provides a sturdy and reliable barrier, critical for maintaining control over flocks during crucial procedures.

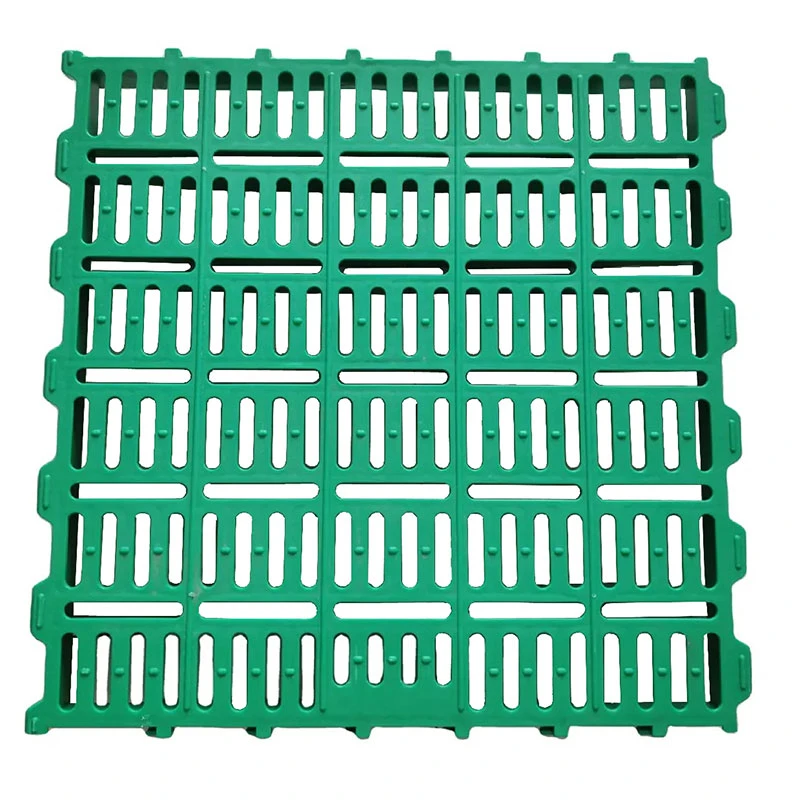

The image above illustrates the practical application and robust construction of our Sheep Fence And Restraint In Sheep Farming Equipment, demonstrating its integration into a functional sheep handling system. This visual testament reinforces the product's suitability for demanding farm environments and its ability to contribute to streamlined operations.

Our Commitment to Quality: Expertise, Authority, and Trust

As a leading provider in livestock equipment, our dedication to quality in galvanised sheep hurdles for sale is underpinned by adherence to stringent industry standards and a customer-centric approach. Our products, including the Sheep Fence And Restraint In Sheep Farming Equipment, are designed and manufactured with the highest levels of expertise, ensuring peak performance and longevity in challenging agricultural environments.

Expertise & Experience:

Our engineering team possesses deep expertise in steel fabrication and protective coatings, honed over decades of service to the agricultural sector. We understand the specific stresses and environmental factors that affect farm equipment, allowing us to engineer hurdles that not only meet but exceed expectations. We've successfully supplied solutions to numerous large-scale sheep farms and agricultural cooperatives across various regions, helping them optimize their animal management practices. Customer feedback consistently highlights the superior strength, easy handling, and remarkable lifespan of our galvanised sheep hurdles.

Authoritativeness & Trustworthiness:

Our manufacturing processes are certified to ISO 9001:2015 for quality management, ensuring consistency and reliability from raw material sourcing to final product delivery. The galvanization process strictly follows ISO 1461:2009, guaranteeing a minimum coating thickness and thereby ensuring optimal corrosion resistance. Every batch of sheep hurdles for sale undergoes rigorous in-house testing, including load-bearing capacity and impact resistance tests, with detailed data sheets available upon request. We are proud to serve as a trusted partner for farmers seeking durable and effective livestock solutions. Our commitment extends beyond the sale, with comprehensive after-sales support and clear warranty terms, typically offering a 5-year warranty against manufacturing defects and premature corrosion. Standard delivery times range from 2-4 weeks, depending on order volume and customization requirements, with expedited options available.

Customization and Solutions:

Recognizing that every farm has unique requirements, we offer custom fabrication services for galvanised sheep hurdles for sale. Whether you need specific lengths, heights, gate integrations, or unique connection systems, our design team can work with you to develop tailored solutions that perfectly fit your operational workflow and infrastructure. This bespoke approach ensures maximum efficiency and cost-effectiveness for our clients.

Frequently Asked Questions (FAQ) about Galvanised Sheep Hurdles

-

Q: What is hot-dip galvanization and why is it important for sheep hurdles?

A: Hot-dip galvanization is a process where fabricated steel is immersed in molten zinc. This creates a highly durable, corrosion-resistant coating that metallurgically bonds with the steel. For galvanised sheep hurdles for sale, it's critical because it protects against rust from moisture, animal waste, and agricultural chemicals, significantly extending their service life and reducing maintenance. -

Q: How long do galvanised sheep hurdles typically last?

A: With proper hot-dip galvanization adhering to ISO 1461 standards (minimum 85 microns thickness), galvanised hurdles can last 20 to 30 years or more in typical agricultural environments, far outperforming painted or untreated steel hurdles. -

Q: Can these hurdles be easily moved and reconfigured?

A: Yes, their modular design and standard connecting pins allow for quick and easy setup, dismantling, and reconfiguration. This flexibility is a key advantage for creating temporary pens, sorting races, or adapting to different pasture sizes. Even larger units like 6ft sheep hurdles for sale are designed for ease of handling by one or two persons. -

Q: Are there different sizes of galvanised sheep hurdles available?

A: Absolutely. Our range includes various standard lengths from 1.2m (4ft) to 3.6m (12ft), and heights suitable for different sheep breeds. Custom sizes are also available upon request to meet specific farm layouts or operational needs. -

Q: What is the typical lead time for an order of hurdles?

A: Standard orders for our Sheep Fence And Restraint In Sheep Farming Equipment typically have a lead time of 2-4 weeks. For large volume orders or custom specifications, lead times will be confirmed at the time of quotation.

Conclusion: The Smart Investment for Sustainable Livestock Farming

Investing in high-quality galvanised sheep hurdles for sale is a strategic decision for any modern sheep farming operation. The superior corrosion resistance provided by hot-dip galvanization ensures an extended service life, minimizing replacement costs and maintenance efforts. Coupled with robust construction and versatile application capabilities, these hurdles facilitate efficient, humane, and sustainable livestock management. Our Sheep Fence And Restraint In Sheep Farming Equipment stands as a testament to engineering excellence, offering unmatched durability, reliability, and adaptability to meet the dynamic needs of today's agricultural landscape. By choosing our certified and expertly crafted hurdles, farmers secure a critical asset that contributes to long-term productivity and operational resilience.

References

- American Society for Testing and Materials. (2019). ASTM A36/A36M, Standard Specification for Carbon Structural Steel.

- International Organization for Standardization. (2009). ISO 1461: Hot-dip galvanized coatings on fabricated iron and steel articles — Specifications and test methods.

- International Organization for Standardization. (2015). ISO 9001: Quality management systems — Requirements.

- American Welding Society. (2020). AWS D1.1/D1.1M: Structural Welding Code – Steel.

Post time: Aug . 11, 2025