Optimizing Livestock Management with Advanced Cattle Headlocks

In the landscape of modern livestock farming, efficiency, animal welfare, and productivity are paramount. Advanced feeding and handling solutions are no longer luxuries but essential investments for sustainable operations. Among these, the integration of high-quality cattle headlocks stands out as a foundational element, transforming routine tasks into streamlined processes. These indispensable pieces of equipment are designed to safely restrain cattle, facilitating a wide range of activities from feeding to health checks, breeding, and sorting, ultimately enhancing farm profitability and animal well-being. For producers seeking robust and reliable solutions, understanding the specifications and benefits of top-tier cattle headlocks for sale is critical.

The demand for sophisticated livestock equipment has driven significant advancements in design and material science. Modern headlocks offer unparalleled durability, ease of use, and animal safety, moving beyond rudimentary designs to incorporate features that cater to the dynamic needs of large-scale dairy and beef operations. From individual locking mechanisms to self-locking systems, these tools provide farmers with precise control, minimizing stress on animals and maximizing the efficiency of farm labor. Investing in superior headlock technology is a strategic move towards a more organized, productive, and humane livestock management system.

Understanding Headlock Technology: Design and Functionality

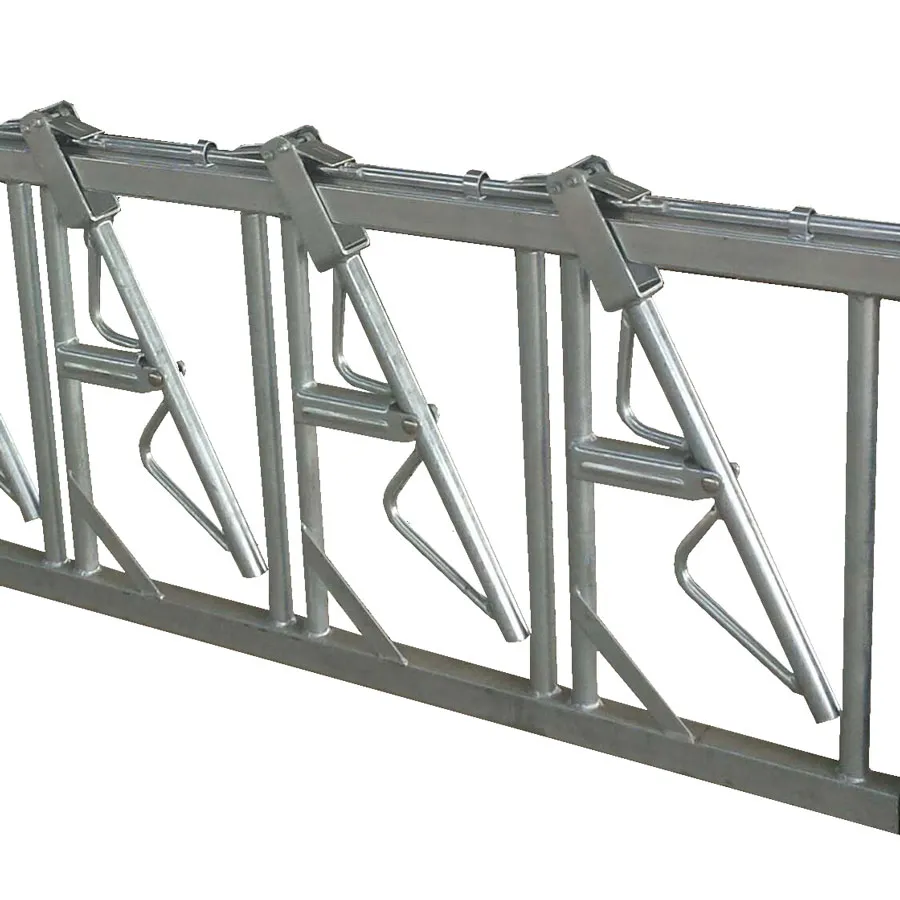

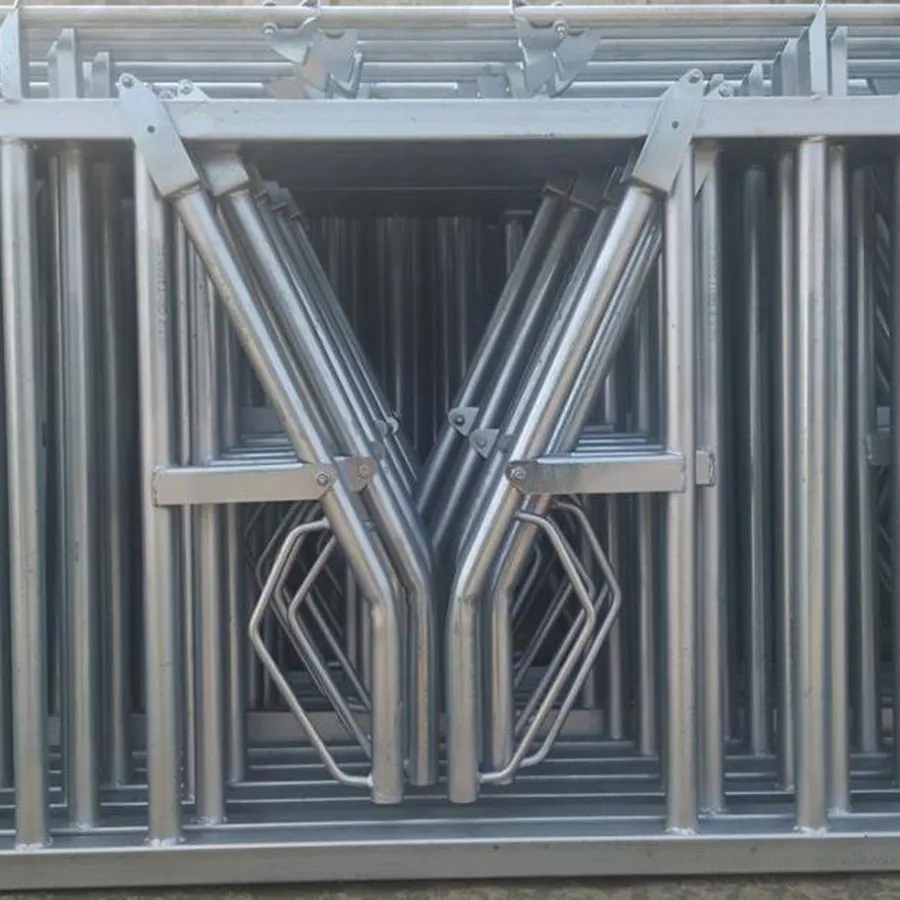

Cattle headlocks, also known as head gates or self-locking feed barriers, are engineered to provide secure individual animal restraint. The core mechanism typically involves a series of pivoting or sliding panels that close around an animal's neck when it extends its head through the feeding aperture. Two primary types dominate the market: individual release headlocks and self locking head gates for sale. Individual release models allow each animal to be manually unlocked, offering maximum control, which is ideal for veterinary procedures or artificial insemination (AI). In contrast, self-locking systems engage automatically when the animal inserts its head, making them highly efficient for mass feeding and general management.

The functionality of these systems extends beyond simple restraint. They are instrumental in promoting controlled feeding, ensuring each animal receives its designated portion and preventing feed waste. For health management, headlocks facilitate safe access for vaccinations, dehorning, tagging, and routine health checks, significantly reducing the risk of injury to both the animal and the handler. Moreover, for growing calves, specialized calf headlocks for sale are designed with adjustable neck spaces and lower heights to accommodate their smaller stature, ensuring safety and comfort while still providing the necessary restraint for young stock management. The ergonomic design and robust construction are vital for longevity and consistent performance in demanding farm environments.

The Precision Manufacturing of High-Quality Cattle Headlocks

The manufacturing of durable cattle headlocks for sale involves a meticulous process to ensure optimal performance and longevity under demanding agricultural conditions. It begins with the careful selection of high-grade materials, typically heavy-duty steel, known for its superior strength and resistance to mechanical stress. This material undergoes precision cutting and forming processes to create the individual components, including the robust frames, pivoting mechanisms, and neck bars.

Following component fabrication, advanced welding techniques, often robotic, are employed to ensure structural integrity and precise alignment, minimizing potential stress points. A critical step in extending the product's service life is the corrosion protection treatment. Hot-dip galvanization, conforming to ISO 1461 standards, is commonly applied. This process involves immersing the fabricated steel in molten zinc, creating a metallurgical bond that provides an exceptionally durable and long-lasting coating, highly resistant to rust, acids, and disinfectants commonly found in farm environments. Quality control is paramount throughout, with inspections conducted at each stage from raw material verification to final product assembly, ensuring compliance with internal standards and often ISO 9001 quality management systems. This stringent process ensures the final product delivers outstanding durability, exceptional labor efficiency, and superior animal safety, making it ideal for modern large-scale dairy farms, beef cattle operations, and advanced agricultural facilities.

Key Technical Specifications and Performance Metrics

When evaluating cattle headlocks for sale, specific technical parameters dictate their suitability for various operations. These specifications ensure the headlocks are not only robust but also tailored to the specific needs of different animal sizes and farm layouts. Understanding these metrics is crucial for B2B decision-makers to select the most cost-effective and efficient solution.

Typical Technical Parameters for Cattle Headlocks

Product Comparison: Standard vs. Heavy-Duty Headlocks

The choice between standard and heavy-duty headlocks depends on the specific demands of the farm, including the size and temperament of the herd, expected usage frequency, and long-term investment strategy. For operations with larger or more active cattle, the enhanced structural integrity and wear resistance of heavy-duty units like the Cattle Head Lock For Cattle Farming Equipment offer significant advantages in terms of durability and reduced maintenance over time.

Real-World Application and Operational Excellence

The strategic deployment of cattle headlocks for sale translates directly into improved farm operations and animal welfare. In typical dairy farms, headlocks are integral to feed alley management, allowing for precise feeding, efficient bunk cleaning, and observation of individual feed intake. During herd health checks, the ability to safely restrain each animal minimizes stress and enables veterinarians and farm staff to perform examinations, administer treatments, and collect samples with greater accuracy and safety. This systematic approach reduces the risk of injury to both animals and personnel, a critical factor in maintaining a safe working environment.

For beef cattle operations, especially those involved in intensive feeding programs, self-locking head gates are invaluable for maintaining feed consistency and managing animal groups. They can be utilized for sorting animals based on weight, health status, or breeding cycles, streamlining daily routines. The benefit of specialized calf headlocks for sale extends to early calf management, facilitating dehorning, tagging, and vaccination procedures at a young age, contributing to better long-term health outcomes and easier handling as they grow. Customer feedback consistently highlights the labor savings, enhanced animal safety, and overall improvement in farm productivity as key advantages of incorporating high-quality headlock systems.

"Implementing CX Livestock's headlocks transformed our feeding routine. We've seen a significant reduction in feed waste, and our vets appreciate the secure handling for health checks. The durability is outstanding, even with our large herd. It's truly a game-changer for daily farm management." - John D., Dairy Farm Owner, Wisconsin, USA.

Ensuring Quality and Trust: Certifications and Support

Commitment to quality and customer trust is the cornerstone of any reputable manufacturer of livestock equipment. For cattle headlocks for sale, this commitment is demonstrated through adherence to international standards and comprehensive customer support. Manufacturers often operate under ISO 9001 certified quality management systems, ensuring that every stage from design to production and delivery meets stringent quality benchmarks. This includes rigorous material testing, precise fabrication tolerances, and final product inspections to guarantee optimal performance and safety.

Beyond manufacturing excellence, reliable suppliers provide robust warranty policies, typically covering structural integrity and functionality for several years. Delivery cycles are streamlined to ensure timely arrival of equipment, minimizing downtime for farm operations. Furthermore, dedicated customer support teams offer expert advice on installation, maintenance, and troubleshooting, providing a seamless experience from inquiry to post-purchase support. This holistic approach ensures that clients not only receive a superior product but also gain a trusted partner committed to their long-term success.

Frequently Asked Questions (FAQ) about Cattle Headlocks

- Q: What is the typical lifespan of a hot-dip galvanized cattle headlock?

A: With proper installation and maintenance, a high-quality hot-dip galvanized headlock can last 15-20 years or more, thanks to its superior corrosion resistance. - Q: Can these headlocks accommodate different sizes of cattle?

A: Yes, most modern cattle headlocks for sale feature adjustable neck openings to safely restrain a range of sizes, from calves (with specialized calf headlocks for sale) to adult cows and bulls. - Q: Are group release or individual release headlocks better?

A: It depends on your operation. Group release (self locking head gates for sale) are excellent for mass feeding and general restraint. Individual release offers precise control for veterinary procedures or AI, allowing you to release specific animals without disturbing others. Many farms use a combination. - Q: What is the recommended delivery lead time for a bulk order?

A: Delivery times vary based on order size and destination, but typically range from 4-8 weeks from order confirmation. Expedited options may be available upon request. - Q: Is installation complicated?

A: While professional installation is recommended, most headlocks are designed for straightforward assembly with clear instructions. Detailed technical drawings and support are usually provided.

Conclusion

Investing in high-quality cattle headlocks for sale is a strategic decision for any modern livestock operation aiming to enhance efficiency, safety, and animal welfare. From precision manufacturing processes ensuring long-term durability to their versatile application in daily farm management, these systems are critical tools for optimizing productivity. By carefully considering technical specifications, opting for robust construction like hot-dip galvanized steel, and partnering with reputable manufacturers, farm managers can secure equipment that delivers significant returns on investment and supports sustainable agricultural practices for years to come.

References

- American Society of Agricultural and Biological Engineers (ASABE) Standards. "ANSI/ASABE S412.1 DEC2017: Safety of livestock equipment."

- International Organization for Standardization (ISO). "ISO 9001:2015 - Quality management systems — Requirements."

- International Organization for Standardization (ISO). "ISO 1461:2009 - Hot dip galvanized coatings on fabricated iron and steel articles — Specifications and test methods."

- Journal of Dairy Science. "Impact of headlock design on feeding behavior and welfare in dairy cattle."

- Livestock Production Science. "Effectiveness of self-locking head gates in managing beef cattle for health interventions."

Post time: Aug . 15, 2025