The Strategic Role of Advanced Hog Feeder Systems in Modern Swine Production

In the rapidly evolving landscape of modern livestock management, the efficiency and precision of feeding systems are paramount to profitability and animal welfare. A sophisticated hog feeder is not merely a dispenser but a critical component of a comprehensive farm automation strategy, significantly influencing feed conversion rates, growth consistency, and overall herd health. As global demand for pork products continues to rise, driven by population growth and changing dietary preferences, producers are increasingly seeking advanced hog raising equipment solutions that offer superior durability, enhanced automation, and precise nutritional delivery. This paradigm shift from traditional methods to technologically integrated feeding systems underscores a broader industry trend towards data-driven farming, aiming to minimize waste, optimize resource utilization, and ensure sustainable production practices. The integration of smart sensors, remote monitoring capabilities, and automated dispensing mechanisms exemplifies the commitment to precision livestock farming, where every gram of feed and every environmental factor is meticulously controlled to maximize output and minimize operational costs. Furthermore, the selection of appropriate feeder types, from large-capacity communal feeders to specialized small hog feeders designed for specific growth stages or individual animal monitoring, directly impacts the efficiency of feed intake and the reduction of feed spillage, which can account for significant economic losses over time. Our focus here is on elucidating the intrinsic value and technological sophistication embedded within contemporary hog feeding solutions, providing a detailed perspective for B2B stakeholders considering strategic investments in swine farming infrastructure.

The market for hog feeder technology is experiencing robust growth, fueled by innovations in material science and digital integration. Current industry trends point towards a strong emphasis on smart feeding systems that can adapt to varying feed types, manage multi-phase feeding programs, and provide real-time data on consumption patterns. This allows for immediate adjustments to optimize feed composition and quantity, responding dynamically to the needs of different pig cohorts or even individual animals. For instance, advanced sensor technologies can detect animal presence and adjust feed delivery accordingly, preventing overfeeding or underfeeding. Beyond feed efficiency, these systems contribute significantly to environmental sustainability by reducing nutrient runoff and minimizing the ecological footprint associated with swine production. Furthermore, the drive for enhanced biosecurity and reduced manual labor is accelerating the adoption of fully automated feeding solutions, freeing up farm personnel to focus on animal health and overall farm management. The transition to higher quality, more durable materials, such as specific grades of stainless steel or robust engineered plastics, in the construction of hog feeder units is another key trend, ensuring longevity and resistance to the corrosive farm environment. These material advancements are crucial for maintaining hygiene standards and extending the operational lifespan of equipment, thereby reducing the total cost of ownership for commercial swine operations. The continued investment in research and development within the agricultural technology sector is poised to introduce even more sophisticated solutions, further refining feeding precision and automating complex tasks to support scalable and sustainable pork production globally.

Precision Engineering: The Manufacturing Process of a High-Performance Hog Feeder

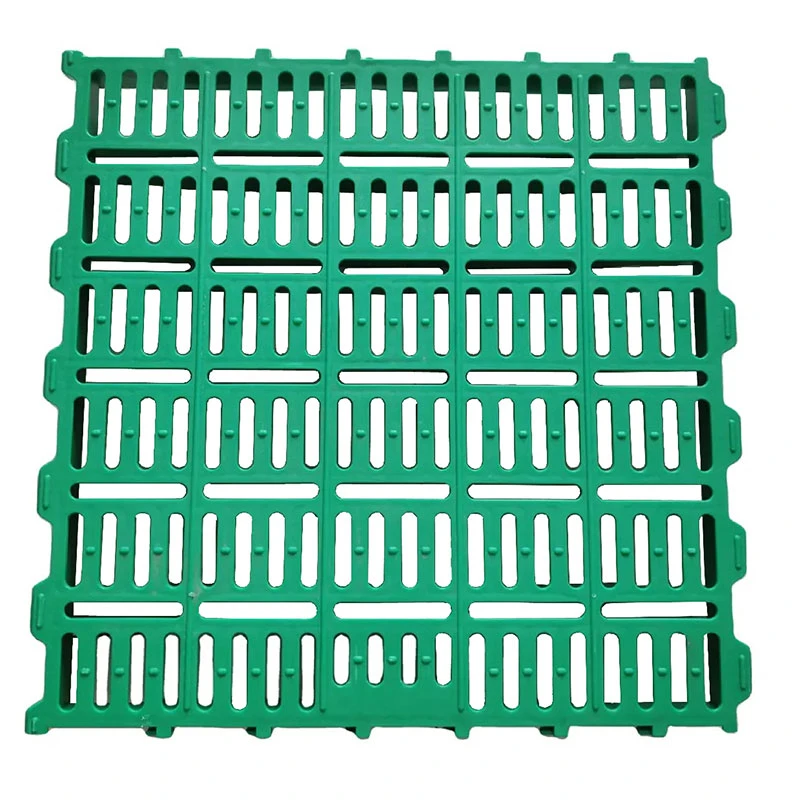

The superior performance and longevity of a modern hog feeder are directly attributable to a meticulous manufacturing process that integrates advanced material selection with precision engineering techniques. The journey begins with the careful selection of raw materials, primarily high-grade stainless steel (e.g., SUS304 for corrosion resistance and hygiene) or robust, food-grade polypropylene (PP) plastics, chosen for their durability, non-toxicity, and resistance to the harsh, often acidic, farm environment. For metal components, the manufacturing flow typically involves processes such as laser cutting for precise panel dimensions, followed by CNC (Computer Numerical Control) bending and welding to form structural elements and hoppers. This ensures accurate fit-up and robust joints capable of withstanding continuous use and aggressive cleaning regimens. Components like dispensing mechanisms often utilize precision casting or forging to achieve intricate shapes with high mechanical strength and wear resistance, followed by CNC machining for exact tolerances on critical surfaces. This level of precision minimizes friction, ensures smooth feed flow, and reduces maintenance requirements over the equipment's lifespan.

Quality control is integrated at every stage, not just at the final assembly. In-process inspections verify material integrity, dimensional accuracy, and weld quality against stringent standards such as ISO 9001 for quality management systems and ANSI standards for specific mechanical properties. Surface treatments, including polishing or powder coating (for non-contact surfaces), are applied to enhance corrosion resistance and facilitate easy cleaning, crucial for biosecurity. Each finished hog feeder unit undergoes a series of rigorous functional tests, including feed flow consistency tests, dispense accuracy calibration, and durability simulations, mimicking years of operational stress. This ensures that the product meets or exceeds expected performance benchmarks for feed conversion efficiency and operational reliability. The anticipated service life of a well-engineered hog feeder, especially those constructed from premium stainless steel, can extend beyond 15-20 years, even under intensive farming conditions, offering a significant return on investment. The advanced manufacturing methodologies employed in producing high-quality hog feeder and hog raising equipment ensures that these systems are not only robust and hygienic but also energy-efficient in terms of feed delivery and operational cycles. This meticulous attention to detail at every manufacturing phase ensures that the final product excels in demanding agricultural environments, delivering consistent performance and contributing to the overall profitability of swine operations.

Technical Parameters and Performance Benchmarks of Leading Hog Feeder Systems

Selecting the optimal hog feeder requires a thorough understanding of its technical specifications and how these parameters translate into real-world performance. Key technical parameters include feed capacity, material of construction, feeding mechanism (e.g., dry, wet-dry, liquid), number of feeding spaces, dimensions, and integration capabilities with existing farm management systems. For instance, a typical large-capacity dry hog feeder for finishing pigs might offer a hopper capacity ranging from 150 kg to 500 kg, constructed from SUS304 stainless steel, featuring adjustable feed gates and a robust agitation system to prevent bridging. Smaller small hog feeders designed for farrowing or nursery stages might have capacities of 20-50 kg, often made from high-density polyethylene (HDPE) for ease of cleaning and portability, featuring precise portion control mechanisms. The feeding mechanism is crucial: dry feeders are simpler and cost-effective, while wet-dry feeders, by mixing feed with water at the point of delivery, can significantly improve feed intake and digestion, especially beneficial for weaned piglets. Liquid feeding systems, while more complex and costly to install, offer the highest precision in nutrient delivery and can incorporate by-products, reducing feed costs and optimizing specific dietary formulations for different growth phases.

Performance benchmarks are critical for evaluating the return on investment of hog feeder systems. Metrics such as feed conversion ratio (FCR), daily weight gain (DWG), and feed spillage rates are directly impacted by feeder design and functionality. A well-designed feeder minimizes spillage, typically reducing it to less than 1-2%, compared to 5-10% or more with inefficient designs. Automation features, such as timed feeding or sensor-based demand feeding, can significantly improve FCR by ensuring pigs consume feed when most active and in optimal quantities, avoiding both overconsumption and hunger stress. For example, studies have shown that automated wet-dry feeders can improve FCR by 5-10% compared to traditional dry feeders, leading to substantial savings in feed costs over a production cycle. Longevity, ease of cleaning, and maintenance requirements also factor into overall performance. A feeder that is difficult to clean can compromise biosecurity and animal health, leading to increased veterinary costs. The integration with environmental control systems, such as the Cooler And Heater In Pig Farming Equipment, further optimizes the feeding environment by ensuring ideal ambient temperatures, which directly affects feed intake and growth rates. This holistic approach to hog raising equipment, combining precise feeding with optimal environmental conditions, significantly enhances productivity and animal welfare, underscoring the technical interplay between various farm components for maximal operational efficiency.

Typical Hog Feeder Technical Specifications

| Parameter | Dry Feeder (Finishing) | Wet-Dry Feeder (Grower-Finisher) | Small Hog Feeder (Nursery) |

|---|---|---|---|

| Capacity (kg) | 150 - 500 | 100 - 300 | 20 - 50 |

| Material | SUS304 Stainless Steel / Galvanized Steel | SUS304 Stainless Steel / PVC | High-Density Polyethylene (HDPE) / SUS304 SS |

| Feeding Mechanism | Adjustable Dry Feed Gate, Gravity-fed | Wet-Dry Nipple Drinker, Demand-fed | Precise Dispensing, Manual/Semi-automated |

| Number of Feeding Spaces | 10 - 20 (depending on size) | 8 - 16 (depending on size) | 4 - 8 |

| Typical Application | Finishing Units, Large Group Pens | Grower-Finisher Barns, Improved FCR | Farrowing Crates, Nursery Pens |

| Estimated Lifespan (Years) | 15+ | 12+ | 8+ |

Application Scenarios and Strategic Advantages of Advanced Hog Feeder Systems

The versatility of modern hog feeder systems allows for their strategic deployment across various stages of swine production, from farrowing and nursery to grower and finisher phases, each demanding specific feeding solutions. In farrowing crates, compact, highly accessible small hog feeders are crucial for providing sows with consistent, high-energy diets essential for lactation and for introducing creep feed to piglets. These feeders often feature anti-spill designs and robust construction to withstand the active environment. For nursery pigs, precision feeders minimize stress and ensure optimal nutrient intake during the critical post-weaning period, a time when feed intake can significantly impact long-term growth. Automated feeders with adjustable drop-rate mechanisms are preferred here to prevent feed wastage and ensure piglets have continuous access to fresh feed. In the grower-finisher stages, where the bulk of feed consumption occurs, large-capacity, robust hog feeder units are indispensable. Wet-dry feeders are particularly advantageous in these stages, as the availability of water alongside dry feed encourages greater consumption and improved feed conversion, often leading to faster growth rates and earlier market weights. The economic advantages are clear: by improving feed efficiency, these systems directly reduce the largest operational cost in swine production—feed.

Beyond direct feed efficiency, advanced hog feeder systems offer a suite of technical advantages that contribute to overall farm sustainability and profitability. Energy efficiency, while not always overtly visible in a feeder itself, is often realized through reduced labor requirements for manual feeding and better utilization of feed, which is energy-intensive to produce. The robust materials and designs ensure exceptional corrosion resistance, crucial in ammonia-rich barn environments, thereby extending equipment lifespan and reducing replacement costs. This anti-corrosion property is vital for maintaining hygiene and preventing bacterial buildup, contributing directly to animal health and biosecurity. Furthermore, the integration capabilities of modern feeders with central farm management software allow for real-time data collection on feed consumption, providing valuable insights for herd health monitoring, early disease detection through changes in eating patterns, and precise inventory management. This data-driven approach allows producers to fine-tune their feeding strategies, optimize feed formulations, and make informed decisions that impact productivity and profitability. The modular design of many contemporary hog raising equipment components, including feeders, also facilitates easy expansion and adaptation to changing farm needs, ensuring that initial investments remain viable and scalable for future growth.

Evaluating Your Investment: Manufacturer Comparison and Custom Solutions for Hog Feeder Systems

When considering a substantial investment in hog feeder systems, a thorough manufacturer comparison is indispensable. Key differentiators among suppliers typically include product innovation, material quality, manufacturing precision, after-sales support, and pricing models. Reputable manufacturers often hold certifications like ISO 9001, attesting to their commitment to quality management systems, and their products may comply with specific agricultural equipment standards. Beyond basic functionality, evaluate manufacturers based on their ability to provide advanced features such as remote monitoring, automated cleaning systems, and integration with comprehensive farm management platforms. For example, some manufacturers specialize in highly durable stainless steel feeders for large commercial operations, emphasizing longevity and minimal maintenance, while others focus on modular plastic designs ideal for smaller farms or specific applications like small hog feeders for farrowing. Consider the manufacturer's track record, years in the industry, and the breadth of their product offerings in hog raising equipment to gauge their expertise and reliability. Engaging with existing clients or reviewing independent performance reports can provide invaluable insights into real-world product reliability and service effectiveness.

Comparative Analysis: Leading Hog Feeder Manufacturers

| Feature | Manufacturer X (Premium) | Manufacturer Y (Mid-Range) | Manufacturer Z (Value) |

|---|---|---|---|

| Primary Material | SUS304/316 Stainless Steel | Galvanized Steel / HDPE | Galvanized Steel / PP |

| Feeding Mechanism | Smart Wet-Dry, Sensor-controlled | Adjustable Dry / Wet-Dry | Gravity-fed Dry |

| Automation Level | Fully Automated, Remote Monitoring | Semi-automated, Optional Modules | Manual / Basic Timers |

| Integration Capabilities | ERP/Cloud Farm Management | Basic Data Export | Standalone |

| Warranty Period | 5-10 Years Structural | 2-5 Years Structural | 1-2 Years Structural |

Beyond off-the-shelf products, many commercial pig producers benefit immensely from customized hog feeder solutions. This often involves tailoring feeder dimensions, capacities, or integration features to fit specific barn layouts, herd sizes, or unique dietary requirements. Customization can range from slight modifications to existing designs, such as adapting feeder height for different growth stages, to designing bespoke feeding lines for specialized operations. For instance, farms utilizing alternative feed sources or unique dietary supplements may require custom mixing and dispensing mechanisms. Similarly, integrating feeders into an existing automated feeding conveyor system or a sophisticated environmental control system, like the Cooler And Heater In Pig Farming Equipment, often necessitates custom interfaces or control modules. A collaborative approach with a manufacturer that offers strong R&D capabilities and a proven track record in custom fabrication ensures that the final solution perfectly aligns with operational goals, leading to maximum efficiency and long-term value. This includes detailed site assessments, engineering design, prototyping, and comprehensive testing to ensure seamless integration and optimal performance within your specific farm ecosystem.

Real-World Impact: Application Cases and Customer Success with Advanced Hog Feeder Systems

The tangible benefits of investing in advanced hog feeder systems are best illustrated through real-world application cases and demonstrable customer success stories. Consider a large-scale commercial pig farm in Iowa, facing challenges with inconsistent growth rates and high feed wastage due to outdated manual feeding methods. Upon implementing a network of automated wet-dry feeders, synchronized with a central feed delivery system, the farm observed a remarkable improvement. Over 12 months, feed conversion ratio (FCR) improved by an average of 7.5%, leading to an estimated annual saving of over $150,000 in feed costs for a 5,000-head finishing operation. Furthermore, daily weight gain increased by 5%, allowing pigs to reach market weight 5-7 days earlier, significantly enhancing throughput and revenue. This case exemplifies how precision feeding, enabled by technologically advanced hog feeder units, directly translates into economic gains and operational efficiency. The reduced manual labor for feeding also freed up staff to focus on critical aspects of animal health and welfare, leading to an overall healthier herd and lower veterinary expenses.

Another compelling case involved a specialized breeding facility focusing on genetic improvement, where precise nutritional intake for individual sows and piglets was paramount. By integrating a series of small hog feeders equipped with individual animal identification (RFID) and demand-based feeding algorithms, the facility achieved unparalleled control over feed consumption. Sows received precisely tailored diets based on their parity and lactation stage, leading to improved litter size and piglet vitality. Piglets, through their small hog feeders, accessed creep feed more consistently, resulting in heavier weaning weights and reduced post-weaning mortality. The real-time data collected from these feeders allowed for early identification of under-performing animals, enabling timely intervention. Client feedback consistently highlights several recurring themes: significant reduction in feed wastage, improved animal health outcomes, enhanced labor efficiency, and a clearer understanding of feed consumption dynamics. These successes are often underpinned by comprehensive service and support from the manufacturer, including initial system design, installation assistance, operational training, and ongoing technical support, ensuring that farms maximize the value of their hog raising equipment investment.

Ensuring Trust and Support: FAQs, Delivery, and Warranty Commitments for Hog Feeder Systems

Building trust in B2B transactions for critical hog raising equipment like hog feeder systems hinges not only on product quality but also on transparent communication regarding support, delivery, and warranty. A comprehensive FAQ section addresses common queries, demonstrating expertise and foresight. For example, questions often include "What maintenance is required for a wet-dry feeder?", "How do I integrate this feeder with my existing farm management software?", or "What is the typical return on investment for an automated feeding system?" Clear and concise answers provide immediate value and instill confidence. Delivery periods are a critical logistical consideration, especially for large-scale farm projects. Reputable suppliers provide realistic lead times, often detailing typical manufacturing times, shipping logistics, and installation timelines. For specialized or custom orders, a detailed project plan with milestones and expected completion dates is typically provided. Our standard delivery for mass-produced hog feeder units is typically 4-6 weeks from order confirmation, while custom solutions may require 8-12 weeks depending on complexity. Expedited shipping options are often available for urgent requirements, though additional costs apply.

Warranty commitments are a testament to a manufacturer's confidence in their product's durability and performance. Most high-quality hog feeder systems come with a multi-year warranty on structural components, often ranging from 2 to 5 years, with separate warranties for electrical or moving parts. This commitment ensures that clients are protected against manufacturing defects and premature failure under normal operating conditions. Our products typically feature a 5-year warranty on stainless steel structural components and a 2-year warranty on all electromechanical parts, reflecting our adherence to stringent ISO and ANSI quality standards. Comprehensive customer support is equally vital. This includes pre-sales consultation to help clients select the most appropriate hog feeder configuration, technical support during installation and commissioning, and responsive after-sales service for troubleshooting, spare parts, and system upgrades. Many manufacturers also offer training programs for farm staff to ensure optimal operation and maintenance of the new equipment. This holistic approach to client engagement, from initial inquiry to long-term operational support, solidifies trust and fosters enduring partnerships in the agricultural sector, ensuring that investments in hog raising equipment yield sustained benefits.

Frequently Asked Questions (FAQs)

-

Q: What is the optimal cleaning frequency for an automated hog feeder?

A: Optimal cleaning frequency depends on feed type and environmental conditions, but generally, a thorough cleaning every 2-4 weeks for dry feeders and weekly for wet-dry feeders is recommended to maintain hygiene and prevent feed buildup. Regular visual inspections should be conducted daily.

-

Q: Can your hog feeder systems handle various feed formulations?

A: Yes, our feeders are designed with adjustable mechanisms and robust auger systems to accommodate a wide range of feed formulations, including pellets, crumbles, and mash. For highly specialized or liquid feeds, specific models or custom modifications may be required to ensure optimal flow and dispensing accuracy.

-

Q: What technical support is available after purchase?

A: We offer comprehensive post-purchase support including remote troubleshooting via phone/video, on-site technical assistance for complex issues, and a readily available inventory of spare parts. Our technical team is available during business hours to assist with operation, maintenance, and diagnostics.

Further Resources on Swine Management and Feeding Technology

- National Pork Board. (2023). Swine Care Handbook: Best Management Practices.

- Journal of Animal Science. (2022). Advances in Precision Feeding for Swine Production. Vol. 100, Issue 4.

- Purdue University Extension. (2021). Feed Management Strategies for Optimal Pig Growth.

- FAO Corporate Document Repository. (2020). The Future of Livestock Feeding: Issues and Opportunities.

Post time: 8月 . 16, 2025